ecoline – Not just recycled.

Recycled materials – sustainable and environmentally friendly

At a time when the effects of climate change are increasingly making themselves felt and our planet’s resources are becoming ever scarcer, it is more important than ever that we all take responsibility and opt for sustainable measures.

Using recycled polypropylene (recycled PP) offers an effective way of reducing our ecological footprint and making a positive contribution towards protecting the environment. Use of recycled plastic enables us to not only reduce waste and conserve resources, but also cut our CO2 emissions, thus minimising our impact on the environment. By opting for recycled PP, we are demonstrating our commitment to a circular economy and resource-friendly production.

Each and every one of us can play a part in preserving our planet for future generations – so let’s seize the opportunity to use recycled materials and together take advantage of environmentally responsible solutions. It’s time to take action and press ahead with the transformation to a sustainable future.

Together, we can shape the future!

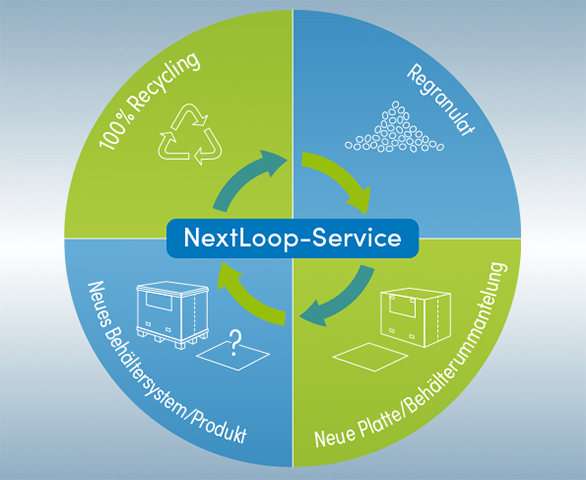

NextLoop service

| Recycling of offcuts, stamping waste, pallet enclosures and other PP industrial waste at our plants in Gera and Haiterbach. | Recovery and processing of top-quality regranulate that is recycled to a high standard and subject to ongoing quality controls in the Infinex Group’s own recycling plants. |

| Use of environmentally friendly structuredcore panels, twin-wall sheets and pallet enclosures in many different branches of industry. At the end of their lifecycle, these products are recycled so they can be returned to the value cycle. | Manufacture of structured-core panels, twin-wall sheets and pallet enclosures. Resource-friendly production from 100% recycled polypropylene. |

Infinex Repoly and the NextLoop service –

the perfect combination

Both structured-core panels and twin-wall sheets are made from pure polypropylene. This is a valuable raw material that should remain in circulation with a view to protecting the environment and conserving resources. Our NextLoop initiative has been providing this important service for many years now. Regardless of what the panels and sheets are used to make, once these products have reached the end of their lifecycle, we are happy to take them back and recycle them so they can be returned to the value cycle.

key element of this environmental service is Infinex Repoly, the recycling company that is part of our Group. Through this company, we can make an important contribution to conserving our resources and protecting the environment. Repoly, the specialist in plastic granulates and compounds, takes PP industrial waste, such as defective pallet enclosures, offcuts, stamping waste and edge trimmings, and turns it into sorted, high-quality recycled material. This allows for precise control over which source materials form part of the recycled material, meaning all products in the new ecoline range can be perfectly tailored to specific customer requirements.

Our commitment to the circular economy and sustainability means we can offer you the opportunity to dispose of your PP products in an eco-friendly way and take a positive step towards protecting the environment. Together, we can help ensure a sustainable future for generations to come.

TRIPLEX – standing strong for the environment

The resource-friendly ecoline product range for TRIPLEX structured-core panels is the environmentally friendly solution for sustainable projects and applications. All ecoline panels and sheets can contribute to sustainability in a variety of ways.

Durable:

Robust and durable, they can be reused for longer, thus reducing the need for single-use materials and preventing waste.

Lightweight:

Depending on the type of panel or sheet, they are extremely stable, yet lightweight. This helps reduce the amount of energy needed to transport the products, thus also cutting CO2 emissions.

Recyclable:

Polypropylene lends itself well to recycling, so recycled PP is also highly suitable for further recycling. TRIPLEX structured-core panels can therefore be optimally recycled after use and utilised in new products. This helps conserve resources and reduce waste.

Versatile:

The versatile panels and sheets are used in a wide range of sectors, such as packaging, the automotive and caravan industries, construction, event management, advertising and agriculture. They can be used to replace all sorts of materials that are difficult or impossible to recycle, thus minimising the impact on the environment.

TRIPLEX structured-core panels – ecoline product range

- Top-quality panel material tailored to the specific application

- Exceptionally lightweight

- Extremely pressure-resistant and shock-resistant

- Easy to process further

- Rot-proof and moisture-resistant

- Excellent chemical resistance

- Smooth or grained surface

- Suitable for various printing methods

- Suitable for thermal lamination with various materials, such as foam, film and non-woven materials

- Available in various colours – white, grey and black

- 100% recyclable

By using structured-core panels and twin-wall sheets made from recycled PP, you can actively help protect the environment and demonstrate your commitment to a sustainable future. Opt for quality, durability and an eco-friendly approach – opt for TRIPLEX panels and KIBO sheets from the recycled PP ecoline product range.